Vegetable oil promises a sustainable alternative to diesel

The thousands of gallons of diesel that data centers store on-site to fuel backup generators in the event of a grid outage are hard to ignore — and do little to assist operators’ drive toward tougher sustainability goals.

In the past two years, an alternative to diesel made from renewable materials has found support among a small number of data center operators: hydrotreated vegetable oil (HVO). HVO is a second-generation biofuel, chemically distinct from “traditional” biodiesel. It can be manufactured from waste food stocks, raw plant oils, used cooking oils or animal fats; and either blended with petroleum diesel or used in 100% concentrations.

This novel fuel reduces carbon dioxide (CO2) emissions by up to 90%, particulate matter by 10% to 30% and nitrogen oxides by 6% to 15%, when compared with petroleum diesel.

Operators that have deployed, or are testing, 100% HVO in their data centers include colocation provider Kao Data, Ark Data Centres, and Datum Datacentres in the UK, Compass Datacenters in the US, Stack Infrastructure in Canada and Interxion in France. The largest colocation provider Equinix said in its most recent 2021 sustainability report that it was piloting HVO at multiple sites and investigating its supply chain for a “transition away from diesel.” Microsoft is using a blend of petroleum diesel and at least 50% HVO in its cloud data centers in Sweden, which were launched at the end of 2021.

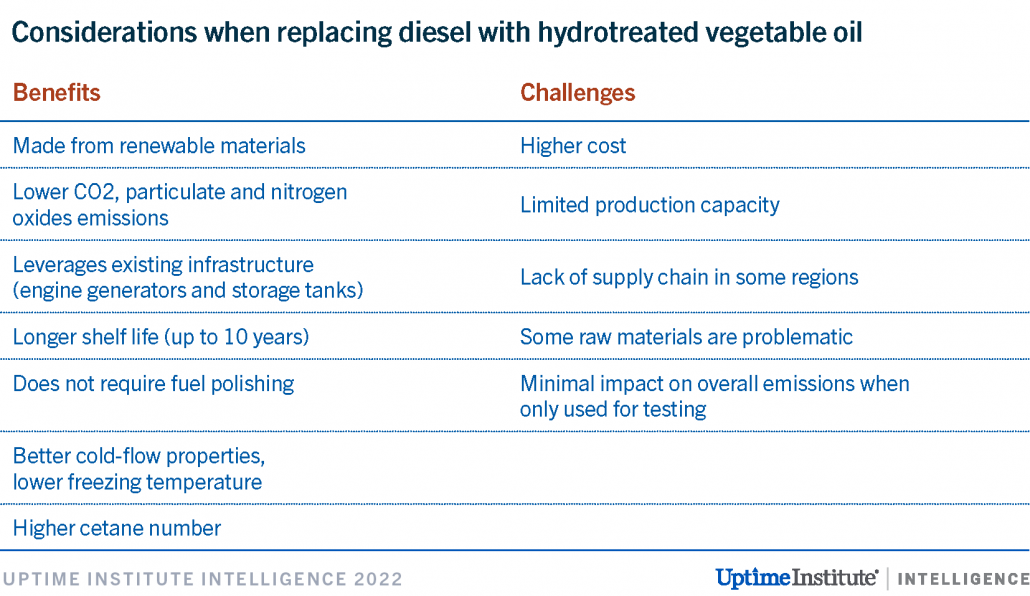

There are several benefits to using 100% HVO in addition to lowered carbon footprint (see Table 1). It can be stored for up to 10 years without major changes to its properties, unlike petroleum diesel, which can only be stored for up to a year. HVO is free from fatty acid methyl ester (FAME), which means it is not susceptible to “diesel bug” (a microbial contamination that grows in diesel) and does not require fuel polishing. HVO also has better cold-flow properties than petroleum diesel that simplify operation in colder climates and delivers slightly more power to the engine due to its high cetane value.

Importantly, HVO serves as a drop-in replacement for diesel: it can be stored in existing tanks, used by most (if not all) existing generators and mixed into existing diesel stocks without changes to parts or processes. Generator vendors that have tested and approved 100% HVO for use with their equipment include Rolls-Royce’s mtu, Cummins, Aggreko, Caterpillar and Kohler; others are likely to follow suit.

However, HVO comes at a price premium: in Europe, it costs about 30% more than traditional diesel fuels.

Another issue is HVO’s currently limited supply. Europe’s first HVO refinery was opened in Finland by oil refiner Neste in 2007; the company remains the world’s largest HVO producer, with four plants in operation.

In the US, there were five commercial HVO plants as of 2020, with a combined capacity of over 590 million gallons per year, according to the US Department of Energy. Most of this capacity was headed to California, due to the economic benefits under the state’s low-carbon fuel standard. For comparison, refineries in the US produced around 69.7 billion gallons of ultra-low-sulfur diesel in 2020.

Production of HVO has been expanding rapidly, owing to its potential as a sustainable aviation fuel. Biofuel broker Greenea expects the number of pure and co-processing HVO plants to triple in the EU, triple in Asia, and rise six-fold in the US between 2020 and 2025.

There is also a potential issue relating to source materials: while HVO can be made from used cooking oils, it can easily be made from palm oil – which can contribute to deforestation and other environmental issues. Large HVO producers are phasing out palm oil from their supply chains; the largest, Neste, plans to achieve this by the end of 2023. Visibility into manufacturing practices and distribution will be a key consideration if HVO is part of data center sustainability strategies.

What is the scale of the potential environmental impact of the use of HVO on data center emissions? While highly resilient data centers are often designed to rely on gensets as their primary source of power, they are rarely used for this purpose in mature data center regions, such as the US and Western Europe, because the electrical grids are relatively stable. Generator testing is, therefore, the main application for HVO in most data centers.

A data center might run each of its generators for only 2 hours of testing per month (24 hours / year). A typical industrial grade, 1-megawatt (MW)-output diesel generator consumes around 70 gallons of fuel per hour at full load. This means a 10 MW facility that has 10 1-MW generators requires up to 16,800 gallons of diesel per year for testing purposes, emitting about 168 metric tons of carbon.

Uptime Institute estimates that for a data center located in Virginia (US) operating at 75% utilization, such a testing regimen would represent just 0.8% of a facility’s Scope 1 and 2 emissions.

The impact on emissions would be greater if the generators were used for longer periods of time. If the same facility used generators to deliver 365 hours of backup power per year, in addition to testing, their contribution to overall Scope 1 and 2 emissions would increase to 8%. In this scenario, a switch to HVO would deliver higher emission reductions.

The relative environmental benefits of switching to HVO would be higher in regions where the grid is most dependent on fossil fuels. However, the impact on the share of emissions produced by generators would be much more pronounced in regions that rely on low-carbon energy sources and have a lower grid emissions factor.

A key attraction of using HVO is that operators do not have to choose one type of fuel over another: since it is a drop-in replacement, HVO can be stored on-site for generator testing and supply contracts for petroleum diesel can be arranged for instances when generators need to be operated for longer than 12 hours at a time. Looking ahead, it remains to be seen whether data center operators are willing to pay a premium for HVO to back up their sustainability claims.

2019

2019