Water cold plates lead in the small, but growing, world of DLC

Direct liquid cooling (DLC), including cold plate and immersion systems, is becoming more common in data centers — but so far this transition has been gradual and unevenly distributed with some data centers using it widely, others not at all. The use of DLC in 2024 still accounts for only a small minority of the world’s IT servers, according to the Uptime Institute Cooling Systems Survey 2024. The adoption of DLC remains slow in general-purpose business IT, and the most substantial deployments currently concentrate on high-performance computing applications, such as academic research, engineering, AI model development and cryptocurrency.

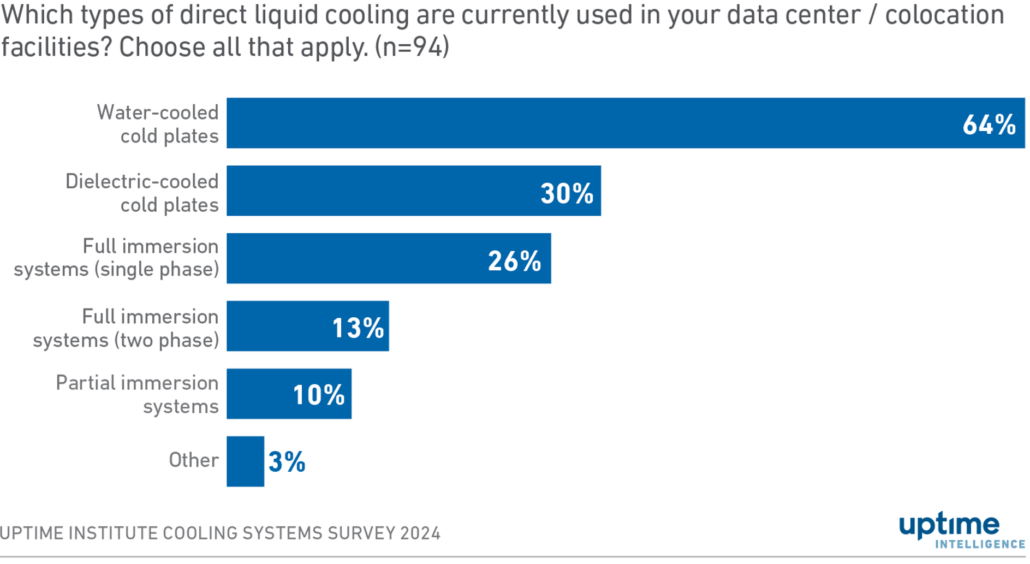

This year’s cooling systems survey results continue a trend: of those operators that use DLC in some form, the greatest number of operators deploy water cold plate systems, with other DLC types trailing significantly. Multiple DLC types will grow in adoption over the next few years, and many installations will be in hybrid cooling environments where they share space and infrastructure with air-cooling equipment.

Within this crowded field, water cold plates’ lead is not overwhelming. Water cold plate systems retain advantages that explain this result: ease of integration into shared facility infrastructure, a well-understood coolant chemistry, greater choice in IT and cooling equipment, and less disruption to IT hardware procurement and warranty compared with other current forms of DLC. Many of these advantages are down to its long-established history spanning decades.

This year’s cooling systems survey provides additional insights into the DLC techniques operators are currently considering. Of those data center operators using DLC, many more (64%) have deployed water cold plates than the next-highest-ranking types: dielectric-cooled cold plates (30%) and single-phase immersion systems (26%) (see Figure 1).

Figure 1. Operators currently using DLC prefer water-cooled cold plates

At present, most users say they use DLC for a small portion of their IT — typically for their densest, most difficult equipment to cool (see DLC momentum rises, but operators remain cautious). These small deployments favor hybrid approaches, rather than potentially expensive dedicated heat rejection infrastructure.

Hybrid cooling predominates — for now

Many DLC installations are in hybrid (mixed) setups in which DLC equipment sits alongside air cooling equipment in the data hall, sharing both heat transport and heat rejection infrastructure. This approach can compromise DLC’s energy efficiency advantages (see DLC will not come to the rescue of data center sustainability), but for operators with only small DLC deployments, it can be the only viable option. Indeed, when operators named the factors that make a DLC system viable, the greatest number (52%, n=392) chose ease of retrofitting DLC into their existing infrastructure.

For those operators who primarily serve mainstream business workloads, IT is rarely dense and powerful enough to require liquid cooling. Nearly half of operators (48%, n=94) only use DLC on less than 10% of their IT racks — and only one in three (33%, n=54) have heat transport and rejection equipment dedicated to their liquid-cooled IT. At this early stage of DLC growth, economics and operational risks dictate that operators prefer cooling technologies that integrate more readily into their existing space. Water cold plate systems can meet this need, despite potential drawbacks.

Cold plates are good neighbors, but not perfect

Water-cooled servers typically fit into standard racks, which simplifies deployment — especially when these servers coexist with air cooled IT. Existing racks can be reused either fully or partially loaded with water-cooled servers, and installing new racks is also straightforward.

IT suppliers prefer to sell the DLC solution integrated with their own hardware, ranging from a single server chassis to rows of racks including cooling distribution units (CDUs). Today, this approach typically favors a cold plate system, so that operators and IT teams have the broadest selection of equipment and compatible IT hardware with vendor warranty coverage.

The use of water in data center cooling has a long history. In the early years of mainframes water was used in part due to its advantageous thermal properties compared with air cooling, but also because of the need to remove heat effectively from the relatively small rooms that computers shared with staff.

Today, water cold plates are used extensively in supercomputing, handling extremely dense cabinets. Operators benefit from water’s low cost and ready availability, and many are already skilled in maintaining its chemistry (even though quality requirements for the water coolant are more stringent for cold plates compared with a facility loop).

The risk (and, in some cases, the vivid memories) of water leakage onto electrified IT components is one reason some operators are hesitant to embrace this technology, but leaks are statistically rare and there are established best practices in mitigation. However, with positive pressure cold plate loops, which is the type most deployed by operators, there is never zero risk. The possibility of water damage is perhaps the single key weakness of water cold plates driving interest in alternative dielectric DLC techniques.

In terms of thermal performance, water is not without competition. Two-phase dielectric coolants show strong performance by taking advantage of the added cooling effect from vaporization. Vendors offer this technology in the form of both immersion tanks and cold plates, with the latter edging ahead in popularity because it requires less change to products and data center operations. The downside of all engineered coolants is the added cost, as well as the environmental concerns around manufacturing and leaks.

Some in the data center industry predict two-phase cooling products will mature to capitalize on their performance potential and eventually become a major form of cooling in the world of IT. Uptime’s survey data suggests that water cold plate systems currently have a balance of benefits and risks that make practical and economic sense for a greater number of operators. But the sudden pressure on cooling and other facility infrastructure brought about by specialized hardware for generative AI will likely create new opportunities for a wider range of DLC techniques.

Outlook

Uptime’s surveys of data center operators are a useful indicator of how operators are meeting their cooling needs, among others. The data thus far suggests a gradual DLC rollout, with water cold plates holding a stable (if not overwhelming) lead. Uptime’s interviews with vendors and operators consistently paint a picture of widespread hybrid cooling environments, which incentivize cooling designs that are flexible and interoperable.

Many water cold plate systems on the market are well suited to these conditions. Looking five years ahead, densified IT for generative AI and other intensive workloads is likely to influence data center business priorities and designs more widely. DLC adoption and operator preferences for specific technology types are likely to shift in response. Pure thermal performance is key but not the sole factor. The success of any DLC technique will rely on overcoming the barriers to its adoption, availability from trusted suppliers and support for a wide range of IT configurations from multiple hardware manufacturers.

Getty Images

Getty Images