Arc Flash Mitigation in the Data Center

Meeting OSHA and NFPA 70E arc flash safety requirements while balancing prevention and production demands

By Ed Rafter

Uninterruptible uptime, 24 x 7, zero downtime…these are some of the terms that characterize data center business goals for IT clients. Given these demands, facility managers and technicians in the industry are skilled at managing the infrastructure that supports these goals, including essential electrical and mechanical systems that are paramount to maintaining the availability of business-critical systems.

Electrical accidents such as arc flash occur all too often in facility environments that have high-energy use requirements, a multitude of high-voltage electrical systems and components, and frequent maintenance and equipment installation activities. A series of stringent standards with limited published exceptions govern work on these systems and associated equipment. The U.S. Occupational Safety and Health Administration (OSHA) and National Fire Protection Association (NFPA) Standard 70E set safety and operating requirements to prevent arc flash and electric shock accidents in the workplace. Many other countries have similar regulatory requirements for electrical safety in the workplace.

When these accidents occur they can derail operations and cause serious harm to workers and equipment. Costs to businesses can include lost work time, downtime, OSHA investigation, fines, medical costs, litigation, lost business, equipment damage, and most tragically, loss of life. According to the Workplace Safety Awareness Council (WPSAC), the average cost of hospitalization for electrical accidents is US$750,000, with many exceeding US$1,000,000.

There are reasonable steps data center operators can—and must—take to ensure the safety of personnel, facilities, and equipment. These steps offer a threefold benefit: the same measures taken to protect personnel also serve to protect infrastructure, and thus protect data center operations.

Across all industries, many accidents are caused by basic mistakes, for example, electrical workers not being properly prepared, working on opened equipment that was not well understood, or magnifying risks through a lack of due diligence. Data center operators, however, are already attuned to the discipline and planning it takes to run and maintain high-availability environments.

While complying with OSHA and NFPA 70E requirements may seem daunting at first, the maintenance and operating standards in place at many data centers enable this industry to effectively meet the challenge of adhering to these mandates. The performance and rigor required to maintain 24 x 7 reliability means the gap between current industry practices and the requirements of these regulatory standards is smaller than it might at first appear, allowing data centers to balance safety with the demands of mission critical production environments.

In this article we describe arc flash and electrical safety issues, provide an overview of the essential measures data centers must follow to meet OSHA and NFPA 70E requirements, and discuss how many of the existing operational practices and adherence to Tier Standards already places many data centers well along the road to compliance.

UNDERSTANDING ARC FLASH

Arc flash is a discharge of electrical energy characterized by an explosion that generates light, noise, shockwave, and heat. OSHA defines it as “a phenomenon where a flashover of electric current leaves its intended path and travels through the air from one conductor to another, or to ground (see Figure 1). The results are often violent and when a human is in close proximity to the arc flash, serious injury and even death can occur.” The resulting radiation and shrapnel can cause severe skin burns and eye injuries, and pressure waves can have enough explosive force to propel people and objects across a room and cause lung and hearing damage. OSHA reports that up to 80% of all “qualified” electrical worker injuries and fatalities are not due to shock (electrical current passing through the body) but to external burn injuries caused by the intense radiant heat and energy of an arc fault/arc blast.1

An arc flash results from an arcing electrical fault, which can be caused by dust particles in the air, moisture condensation or corrosion on electrical/mechanical components, material failure, or by human factors such as improper electrical system design, faulty installation, negligent maintenance procedures, dropped tools, or accidentally touching a live electrical circuit. In short, there are numerous opportunities for arc flash to occur in industrial settings, especially those in which there is inconsistency or a lack of adherence to rigorous maintenance, training, and operating procedures.

Variables that affect the power of an arc flash are amperage, voltage, the distance of the arc gap, closure time, three-phase vs. single-phase circuit, and being in a confined space. The power of an arc at the flash location, the distance a worker is from the arc, and the time duration of their exposure to the arc will all affect the extent of skin damage. The WPSAC reports that fatal burns can occur even at distances greater than 10 feet (ft) from an arc location, in fact, serious injury and fatalities can occur up to 20 ft away. The majority of hospital admissions for electrical accidents are due to arc flash burns, with 30,000 arc incidents and 7,000 people suffering burn injuries per year, 2,000 of those requiring admission to burn centers with severe arc flash burns.2

The severity of an arc flash incident is determined by several factors, including temperature, the available fault current, and the time for a circuit to break. The total clearing time of the overcurrent protective device during a fault is not necessarily linear, as lower fault currents can sometimes result in a breaker or fuse taking longer to clear, thus extending the arc duration and thereby raising the arc flash energy.

Unlike the bolted fault (in which high current flows through a solid conductive material typically tripping a circuit breaker or protective device), an arcing fault uses ionized air as a conductor, with current jumping a gap between two conductive objects. The cause of the fault normally burns away during the initial flash, but a highly conductive, intensely hot plasma arc established by the initial arc sustains the event. Arc flash temperatures can easily reach 14,000–16,000°F (7,760–8,870°C) with some projections as high as 35,000°F (19,400°C)—more than three times hotter than the surface of the sun.

These temperatures can be reached by an arc fault event in as little as a few seconds or even a few cycles. The heat generated by the high current flow may melt or vaporize the conductive material and create an arc characterized by a brilliant flash, intense heat, and a fast-moving pressure wave that propels the arcing products. The pressure of an arc blast [up to 2,000 pounds/square foot (9765 kilograms/square meter)] is due to the expansion of the metal as it vaporizes and the heating of the air by the arc. This accounts for the expulsion of molten metal up to 10 ft away. Given these extremes of heat and energy, arc flashes often cause fires, which can rapidly spread through a facility.

INDUSTRY STANDARDS AND REGULATIONS

To prevent these kinds of accidents and injuries, it is imperative that data center operators understand and follow appropriate safety standards for working with electrical equipment. Both the NFPA and OSHA have established standards and regulations that help protect workers against electrical hazards and prevent electrical accidents in the workplace.

OSHA is a federal agency (part of the U.S. Department of Labor) that ensures safe and healthy working conditions for Americans by enforcing standards and providing workplace safety training. OSHA 29 CFR Part 1910, Subpart S and OSHA 29 CFR Part 1926, Subpart K include requirements for electrical installation, equipment, safety-related work practices, and maintenance for general industry and construction workplaces, including data centers.

NFPA 70E is a set of detailed standards (issued at the request of OSHA and updated periodically) that address electrical safety in the workplace. It covers safe work practices associated with electrical tasks and safe work practices for performing other non-electrical tasks that may expose an employee to electrical hazards. OSHA revised its electrical standard to reference NFPA 70E-2000 and continues to recognize NFPA 70E today.

The OSHA standard outlines prevention and control measures for hazardous energies including electrical, mechanical, hydraulic, pneumatic, chemical, thermal, and other energy sources. OSHA requires that facilities:

• Provide and be able to demonstrate a safety program with defined responsibilities.

• Calculate the degree of arc flash hazard.

• Use correct personal protective equipment (PPE) for workers.

• Train workers on the hazards of arc flash.

• Use appropriate tools for safe working.

• Provide warning labels on equipment.

NFPA 70E further defines “electrically safe work conditions” to mean that equipment is not and cannot be energized. To ensure these conditions, personnel must identify all power sources, interrupt the load and disconnect power, visually verify that a disconnect has opened the circuit, lock out and tag the circuit, test for absence of voltage, and ground all power conductors, if necessary.

LOCKOUT/TAGOUT

Most data center technicians will be familiar with lockout and tagging procedures for disabling machinery or equipment. A single qualified individual should be responsible for de-energizing one set of conditions (unqualified personnel should never perform lockout/tagout, work on energized equipment, or enter high risk areas). An appropriate lockout or tagout device should be affixed to the de-energized equipment identifying the responsible individual (see Figure 2).

OVERVIEW: WORKING ON ENERGIZED EQUIPMENT

As the WPSAC states, “the most effective and foolproof way to eliminate the risk of electrical shock or arc flash is to simply de-energize the equipment.” However, both NFPA 70E and OSHA clarify that working “hot” (on live, energized systems) is allowed within the set safety limits on voltage exposures, work zone boundary requirements, and other measures to take in these instances. Required safety elements include personnel qualifications, hazard analysis, protective boundaries, and the use of PPE by workers.

Only qualified persons should work on electrical conductors or circuit parts that have not been put into an electrically safe work condition. A qualified person is one who has received training in and possesses skills and knowledge in the construction and operation of electric equipment and installations and the hazards involved with this type of work. Knowledge or training should encompass the skill to distinguish exposed live parts from other parts of electric equipment, determine the nominal voltage of exposed live parts, and calculate the necessary clearance distances and the corresponding voltages to which a worker will be exposed.

An arc flash hazard analysis for any work must be conducted to determine the appropriate arc flash boundary, the incident energy at the working distance, and the necessary protective equipment for the task. Arc flash is measured in thermal energy units of calories per square centimeter (calories/cm2) and arc flash analysis is referred to as the incident energy of the circuit. Incident energy is both radiant and convective. It is inversely proportional to the working distance squared and directly proportional to the time duration of the arc and to the available bolted fault current. Time has a greater effect on intensity than the available bolted fault current.

The incident energy and flash protection boundary are both calculated in an arc flash hazard analysis. There are two calculation methods, one outlined in NFPA 70E-2012 Annex D and the other in Institute of Electrical and Electronics Engineers (IEEE) Standard 1584.

In practice, to calculate the arc flash (incident energy) at a location, the amount of fault current and the amount of time it takes for the upstream device to trip must be known. A data center should model the distribution system into a software program such as SKM Power System Analysis, calculate the short circuit fault current levels and use the protective device settings feeding switchboards, panelboards, industrial control panels, and motor control centers to determine the incident energy level.

BOUNDARIES

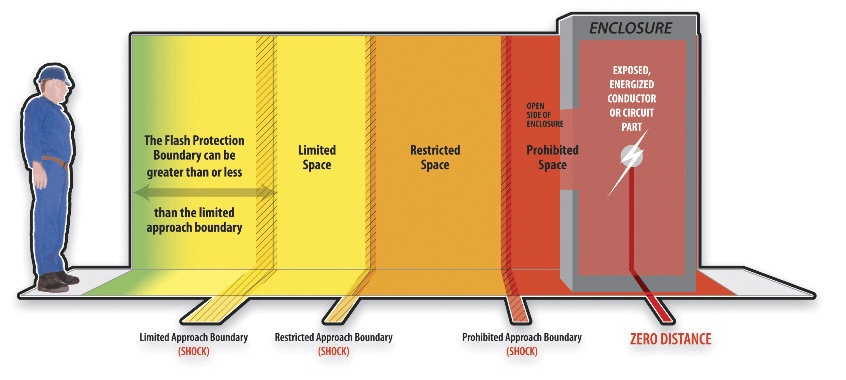

NFPA has defined several protection boundaries: Limited Approach, Restricted, and Prohibited. The intent of NFPA 70E regarding arc flash is to provide guidelines that will limit injury to the onset of second degree burns. Where these boundaries are drawn for any specific task is based on the employee’s level of training, the use of PPE, and the voltage of the energized equipment (see Figure 3).

The closer a worker approaches an exposed, energized conductor or circuit part the greater the chance of inadvertent contact and the more severe the injury that an arc flash is likely to cause that person. When an energized conductor is exposed, the worker may not approach closer than the flash boundary without wearing appropriate personal protective clothing and PPE.

IEEE defines Flash Protection Boundary as “an approach limit at a distance from live parts operating at 50 V or more that are un-insulated or exposed within which a person could receive a second degree burn.” NFPA defines approach boundaries and workspaces as shown in Figure 4. See the sidebar Protection Boundary Definitions.

Calculating the specific boundaries for any given piece of machinery, equipment, or electrical component can be done using a variety of methods, including referencing NFPA tables (easiest to do but the least accurate) or using established formulas, an approach calculator tool (provided by IEEE), or one of the software packages available for this purpose.

PROTECTIVE EQUIPMENT

NFPA 70E outlines strict standards for the type of PPE required for any employees working in areas where electrical hazards are present based on the task, the parts of the body that need protection, and the suitable arc rating to match the potential flash exposure. PPE includes items such as a flash suit, switching coat, mask, hood, gloves, and leather protectors. Flame -resistant clothing underneath the PPE gear is also required.

After an arc flash hazard analysis has been performed, the correct PPE can be selected according to the equipment’s arc thermal performance exposure value (ATPV) and the break open threshold energy rating (EBT). Together, these components determine the calculated hazard level that any piece of equipment is capable of protecting a worker from (measured in calories per square centimeter). For example, a hard hat with an attached face shield provides adequate protection for Hazard/Risk Category 2, whereas an arc flash protection hood is needed for a worker exposed to Hazard/Risk Category 4.

PPE is the last line of defense in an arc flash incident; it’s not intended to prevent all injuries, but to mitigate the impact of a flash, should one occur. In many cases, the use of PPE has saved lives or prevented serious injury.

OTHER SAFETY MEASURES

Additional safety-related practices for working on energized systems could include conducting a pre-work job briefing, using insulated tools, having a written safety program, and flash hazard labeling (labels should indicate the flash hazard boundaries for a piece of equipment, and the PPE needed to work within those boundaries), and completing an Energized Electrical Work Permit. According to NFPA, an Energized Electrical Work Permit is required for a task when live parts over 50 volts are involved. The permit outlines conditions and work practices needed to protect employees from arc flash or contact with live parts, and includes the following information:

• Circuit, equipment, and location

• Reason for working while energized

• Shock and arc flash hazard analysis

• Safe work practices

• Approach boundaries

• Required PPE and tools

• Access control

• Proof of job briefing.

DECIDING WHEN TO WORK HOT

NFPA 70E and OSHA require employers to prove that working in a de-energized state creates more or worse hazards than the risk presented by working on live components or is not practical because of equipment design or operational limitations, for example, when working on circuits that are part of a continuous process that cannot be completely shut down. Other exceptions include situations in which isolating and deactivating system components would create a hazard for people not associated with the work, for example, when working on life-support systems, emergency alarm systems, ventilation equipment for hazardous locations, or extinguishing illumination for an area.

In addition, OSHA makes provision for situations in which it would be “infeasible” to shut down equipment, for example, some maintenance and testing operations can only be done on live electric circuits or equipment. The decision to work hot should only be made after careful analysis of the determination of what constitutes infeasibility. In recent years, some well publicized OSHA actions and statements have centered on the matter of how to interpret this term.

ELECTRICAL SAFETY MEASURES IN PRACTICE

Many operational and maintenance practices will help minimize the potential for arc flash, reduce the incident energy or arcing time, or move the worker away from the energy source. In fact, many of these practices are consistent with the rigorous operational and maintenance processes and procedures of a mission-critical data center.

Although the electrical industry is aware of the risks of arc flash, according to the National Institute for Occupational Safety and Health, the biggest worksite personnel hazard is still electrical shock in all but the construction and utility industries. In his presentation at an IEEE-Industry Applications Society (IAS) workshop, Ken Mastrullo of the NFPA compared OSHA 1910 Subpart S citations versus accidents and fatalities between 1 Oct. 2003, and 30 Sept. 2004. Installations accounted for 80% of the citations, while safe work practice issues were cited 20% of the time. However, installations accounted for 9% of the accidents, while safe work practice issues accounted for 91% of all electrical-related accidents. Looking at Mastrullo’s data, while the majority of the OSHA citations were for installation issues, the majority of the injuries were related to work practice issues.

Can OSHA cite you as a company that does not comply with NFPA 70E? The simple answer is: Yes. If employees are involved in a serious electrical incident, OSHA likely will present the employer/owner with several citations. In fact, OSHA assessed more than 2,880 fines between 2007–2011 for sites not meeting Regulation 1910.132(d), averaging 1.5 fines a day.

On the other hand, an OSHA inspection may actually help uncover issues. A May 2012 study of 800 California companies found that those receiving an inspection saw a decline of 9.4% in injuries. On average, these companies saved US$350,000 over the five years following the OSHA inspections,3 an outcome far preferable to being fined for noncompliance or experiencing an electrical accident. Beyond the matter of fines, however, any organization that wishes to effectively avoid putting its personnel in danger—and endangering infrastructure and operations—should endeavor to follow NFPA 70E guidelines (or their regional equivalent).

REDUCING ARC FLASH HAZARDS IN THE FACILITY

While personnel-oriented safety measures are the most important (and mandated) steps to reduce the risk of arc flash accidents, there are numerous equipment and component elements that can be incorporated into facility systems that also help reduce the risk. These include metal-clad switchgear, arc resistant switchgear, current-limiter power circuit breakers, and current-limiting reactors. Setting up zone selective interlocking of circuit breakers can also be an effective prevention measure.

TIER STANDARDS & DATA CENTER PRACTICES ALIGN WITH ARC FAULT PREVENTION

Data centers are already ahead of many industries in conforming to many provisions of OSHA and NFPA 70E. Many electrical accidents are caused by issues such as dust in the environment, improper equipment installation, and human factors. To maintain the performance and reliability demanded by customers, data center operators have adopted a rigorous approach to cleaning, maintenance, installation, training, and other tasks that forestall arc flash. Organizations that subscribe to Tier standards and maintain stringent operational practices are better prepared to take on the challenges of compliance with OSHA and NFPA 70E requirements, in particular the requirements for safely performing work on energized systems, when such work is allowed per the safety standards.

For example, commissioning procedures eliminate the risk of improper installation. Periodically load testing engine generators and UPS systems demonstrates that equipment capacity is available and helps identify out-of-tolerance conditions that are indicative of degrading hardware or calibration and alignment issues. Thermographic scanning of equipment, distribution boards, and conduction paths can identify loose or degraded connections before they reach a point of critical failure.

Adherence to rigorous processes and procedures helps avoid operator error and are tools used in personnel training and refresher classes. Facility and equipment design and capabilities, maintenance programs, and operating procedures are typically well defined and established in a mission critical data center, especially those at a Tier III or Tier IV Certification level.

Beyond the Tier Topology, the operational requirements for every infrastructure classification, as defined in the Tier Standard: Operational Sustainability, include the implementation of processes and procedures for all work activities. Completing comprehensive predictive and preventive maintenance increases reliability, which in turn improves availability. Methods of procedure are generally very detailed and task specific. Maintenance technicians meet stringent qualifications to perform work activities. Training is essential, and planning, practice, and preparation are key to managing an effective data center facility.

This industry focus on rigor and reliability in both systems and operational practices, reinforced by the Tier Standards, will enable data center teams to rapidly adopt and adhere to the practices required for compliance with OSHA and NFPA 70E. What still remains in question is whether or not a data center meets the infeasibility test prescribed by these governing bodies in either the equipment design or operational limitations.

It can be argued that some of today’s data center operations approach the status of being “essential” for much of the underlying infrastructure that runs our 24x 7 digitized society. Data centers support the functioning of global financial systems, power grids and utilities, air traffic control operations, communication networks, and the information processing that support vital activities ranging from daily commerce to national security. Each facility must assess its operations and system capabilities to enable adherence to safe electrical work practices as much as possible without jeopardizing critical mission functions. In many cases, it may become a jurisdictional decision as to the answer for a specific data center business requirement.

No measure will ever completely remove the risk of working on live, energized equipment. In instances where working on live systems is necessary and allowed by NFPA 70E rules, the application of Uptime Institute Tier III and Tier IV criteria can help minimize the risks. Tier III and IV both require the design and installation of systems that enable equipment to be fully de-energized to allow planned activities such as repair, maintenance, replacement, or upgrade without exposing personnel to the risks of working on energized electrical equipment

CONCLUSION

Over the last several decades, data centers and the information processing power they provide has become a fundamental necessity in our global, interconnected society. Balancing the need for appropriate electrical

safety measures and compliance with the need to maintain and sustain uninterrupted production capacity in an energy-intensive environment is a challenge. But it is a challenge the data center industry is perhaps better prepared to meet than many other industry segments. It is apparent that those in the data center industry who subscribe to high-availability concepts such as the Tier Standards: Topology and Operational Sustainability are in a position to readily meet the requirements of NFPA 70E and OSHA from an execution perspective.

SIDEBAR: PROTECTION BOUNDARY DEFINITIONS

The flash protection boundary is the closest approach allowed by qualified or unqualified persons without the use of PPE. If the flash protection boundary is crossed, PPE must be worn. The boundary is a calculated number based upon several factors such as voltage, available fault current, and time for the protective device to operate and clear the fault. It is defined as the distance at which the worker is exposed to 1.2 cal/cm2 for 0.1 second.

LIMITED APPROACH BOUNDARY

The limited approach boundary is the minimum distance from the energized item where untrained personnel may safely stand. No unqualified (untrained) personnel may approach any closer to the energized item than this boundary. The boundary is determined by NFPA 70E Table 130.4-(1) (2) (3) and is based on the voltage of the equipment (2012 Edition).

RESTRICTED APPROACH BOUNDARY

The restricted approach boundary is the distance where qualified personnel may not cross without wearing appropriate PPE. In addition, they must have a written approved plan for the work that they will perform. This boundary is determined from NFPA Table 130.4-(1) (4) (2012 Edition) and is based on the voltage of the equipment.

PROHIBITED APPROACH BOUNDARY

Only qualified personnel wearing appropriate PPE can cross a prohibited approach boundary. Crossing this boundary is considered the same as contacting the exposed energized part. Therefore, personnel must obtain a risk assessment before the prohibited boundary is crossed. This boundary is determined by NFPA 70E Table 130.4-(1) (5) (2012 Edition) and is based upon the voltage of the equipment.

Edward P. Rafter has been a consultant to Uptime Institute Professional Services (ComputerSite Engineering) since 1999 and assumed a full time position with Uptime Institute in 2013 as principal of Education and Training. He currently serves as vice president-Technology. Mr. Rafter is responsible for the daily management and direction of the professional education staff to deliver all Uptime Institute training services. This includes managing the activities of the faculty/staff delivering the Accredited Tier Designer (ATD) and Accredited Tier Specialist (ATS) programs, and any other courses to be developed and delivered by Uptime Institute.

ADDITIONAL RESOURCES

To review the complete NFPA-70E standards as set forth in NFPA 70E: Standard For Electrical Safety In The Workplace, visit www.NFPA.org

For resources to assist with calculating flash protection boundaries, visit:

• http://www.littelfuse.com/arccalc/calc.html

• http://www.pnl.gov/contracts/esh-procedures/forms/sp00e230.xls

• http:www/bussmann.com/arcflash/index.aspx

To determine what PPE is required, the tables in NFPA 70E-2012 provide the simplest methods for determining PPE requirements. They provide instant answers with almost no field data needed. The tables provide limited application and are conservative for most applications (the tables are not intended as a substitution for an arc hazard analysis but only as a guide).

A simplified two-category PPE approach is found in NFPA 70E-2012, Table H-2 of Annex H. This table ensures adequate PPE for electrical workers within facilities with large and diverse electrical systems. Other good resources include:

• Controlling Electrical Hazards. OSHA Publication 3076, (2002). 71 pages. Provides a basic overview

of basic electrical safety on the job, including information on how electricity works, how to protect

against electricity, and how OSHA cab help.

• Electrical Safety: Safety and Health for Electrical Trades Student Manual, U.S. Department of Health and

Human Services (DHHS). National Institute for Occupational Safety and Health (NIOSH), Publication

No. 2002-123, (2002, January). This student manual is part of a safety and health curriculum for

secondary and post-secondary electrical trades courses. It is designed to engage the learner in

recognizing, electrical, and controlling hazards associated with electrical work.

• Electrocutions Fatality Investigation Reports. National Institute for Occupational Safety and Health

(NIOSH) Safety and Health Topic. Provides information regarding hundreds of fatal incidents involving

electrocutions investigated by NIOSH and state investigators.

• Working Safely with Electricity. OSHA Fact sheet. Provides safety information on working with

generators, power lines, extension cords, and electrical equipment.

• Lockout/Tagout OSHA Fact Sheet, (2002).

• Lockout-Tagout Interactive Training Program. OSHA. Includes selected references for training and

interactive case studies.

• NIOSH Arc Flash Awareness, NIOSH Publication No. 2007-116D.

ENDNOTES

1. http://www.arcsafety.com/resources/arc-flash-statistics

2. Common Electrical Hazards in the Workplace including Arc Flash, Workplace Safety Awareness Council (www.wpsac.org), produced under Grant SH-16615-07-60-F-12 from the Occupational Safety and Health Administration, U.S. Department of Labor.

3. “The Business Case For Safety and Health,” U.S. Department of Labor, https://www.osha.gov/dcsp/products/topics/businesscase/

Getty Images

Getty Images

2020

2020